150 Years of S.B. Foot Tanning: A Storied Past, A Strong Future

If you earn the reputation for producing the highest-quality leather over a period of 150 years, it seems inevitable that other manufacturers in industries outside shoemaking would want to partner with you as well.

This is exactly what has happened at the S.B. Foot Tanning Company, which first gained prominence as the primary supplier for the Red Wing Shoe Company located across town in Red Wing, Minnesota.

Tanning leather for use in footwear still comprises a vast majority of S.B. Foot business. That includes serving as the primary leather supplier for the Red Wing Shoe Company family of brands; being the U.S. military’s largest supplier of leather for combat boots; and providing waterproof and fire-resistant leather for firefighter turnout boots throughout North America.

The leather is also sourced for multiple applications other than boots and shoes. For example, S.B. Foot supplies world-renown watchmakers for manufacturing their leather watchbands. Another company uses the leather to make the wrap for its glass whiskey flasks. S.B. Foot leather is also sold to a hatmaker, several bag makers, a maker of vintage baseballs, and a specialty chair manufacturer.

“One of our most interesting applications is a customer that uses our leather as an O-ring in the transmission of semi-trucks,” said Jeff McDowell, S.B. Foot Tanning Sales Manager. “They’ve found that our leather functions best inside their transmissions at freezing temperatures.”

Exacting quality standards

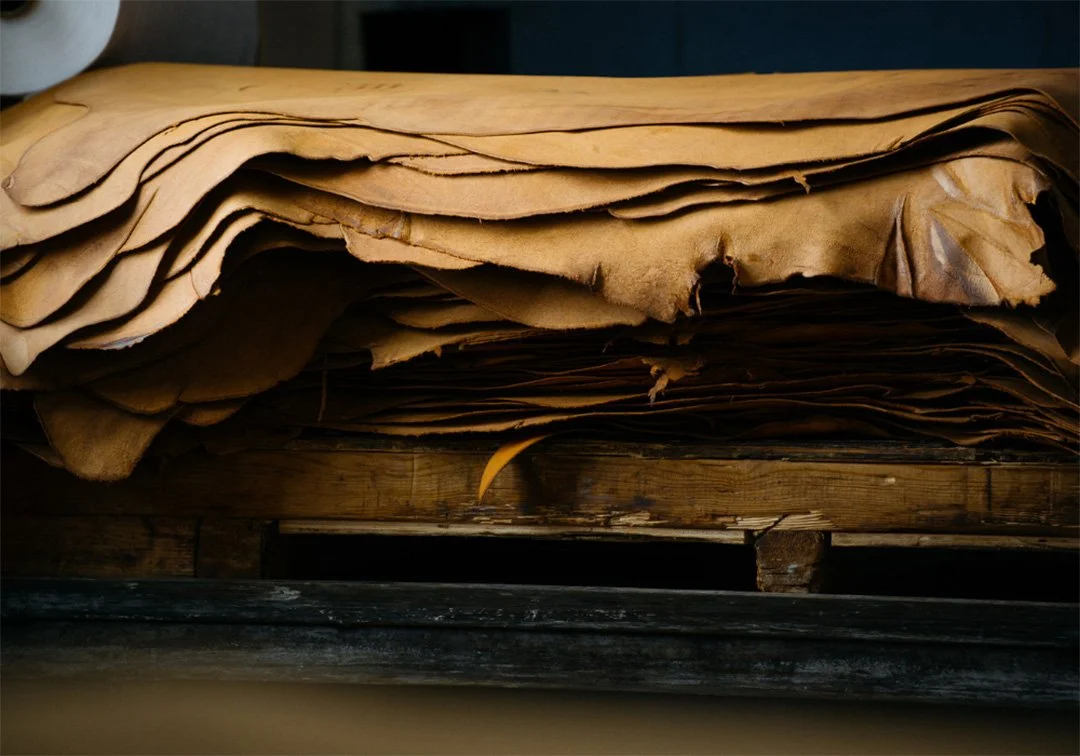

S.B. Foot leather is widely perceived as an American classic that captures the ruggedness and natural beauty of the cattle raised on the Central Plains of Nebraska. The oiled leather is warm to the touch, ages well, and lasts a lifetime.

Two processes that help to make the S.B. Foot end-product so unique are the tannery’s rigorous QA/QC and final testing processes. To ensure quality, the final sorters look closely at every individual piece of leather produced, evaluating whether the color is a close enough match and the leather is cuttable enough to send on to a customer.

Once the leather passes final visual quality inspection, it’s on to the lab to final-test performance characteristics such as waterproofing, absorption levels, tear strength and color fastness. Only then is the leather cleared to head out the factory door and into the world.

“The fact that we test everything that leaves the building is a real advantage in the marketplace,” McDowell said. “Our customers just know they can rely on the quality and consistency of the leather they receive from S.B. Foot, and this peace of mind is one of the most valuable benefits we can offer.”

Aligned with the next potential trend

According to McDowell, one interesting recent development at S.B. Foot Tanning has been skyrocketing demand from distributors who buy its “rejected” leather and resell it to local leathermakers. Much of this leather has minor surface imperfections or other defects which prevent it from going into a boot, making the leather pieces more than sufficient for use in the making of products such belts, bags, and wallets

“Almost all of our rejected leather now gets bought and resold because it is still so high in quality,” McDowell said. “This has been a wonderful way to start the conversation with small regional customers who were previously unknown to us.” As for the future, McDowell sees even more promise in finding value in the currently “rejected” leather pieces that may appear less than perfect to the naked eye.

“I think those distributors may be onto what might be the next trend in leathermaking,” McDowell said. “I think part of the natural beauty of any piece of leather is the unique scratches and scars that it possesses, and I could see the industry pivoting away from only demanding perfection and toward flaws becoming a feature in some cases. This is a much more sustainable approach for both the leather industry and the environment.

“S.B. Foot Tanning has incredibly high standards, and that makes our leather the highest quality out there,” McDowell added. “But I also see an opportunity for us to start using more of the leather ourselves that is beautifully scarred and scratched. At the end of the day, this is what makes it authentic, real, American.”

The next 150 years

S.B. Foot has grown exponentially since 1872 – what started as tanning just a few hides a week has grown to thousands a week. And while much has changed in a century and a half, the original mission – doing things the right way – remains the same to this day. One hundred and fifty years later, the vision and legacy of Silas Buck Foot lives on. S.B. Foot has been at the forefront of providing exceptional leather and craftsmanship to customers here, and around the world.